MuteMat LVT 650 – 1.6

Shipped by iKoustic from the UK

£0.00

£0.00 inc. VAT

Out of stock

Not available to order online please contact us directly.

MuteMat LVT 650 – 1.6

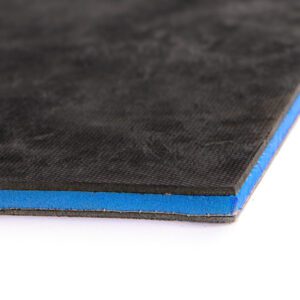

MuteMat LVT 650 – 1.6 is a low weight and low gauge acoustic underlay with excellent impact sound reduction for use under Luxury Vinyl Tiles (LVT). The product has consistently achieved impact sound reduction of 18dB in tested with a standard 2.5mm LVT helping to reduce sound transmission between floors or dwellings.

The MuteMat LVT 650 – 1.6 is simple to install and is adhered to the subfloor before adhering your choice of LVT floor finish to the top, for more detailed information see the installation tab above. The product is also ideal for use with underfloor heating with a low tog rating of just 0.15 making it suitable for a wide range of applications and installations. The Ultra thin gauge of the product helps to reduce finishing heights and to optimise indentation recovery. The material requires bonding to both the subfloor and the final floor finish and therefore forms a permanent solution and part of the building structure. The manufacturing of the product is tightly controlled to provide a consistent density and material for lasting and even performance across the material.

Find out more information about MuteMat LVT 650- – 1.6 by downloading the guides below.

If you are looking to specify this product for a build, please refer to our downloads tab for technical product or systems information.

Technical Support

Should you require further technical assistance in specifying our products, please contact us and ask for our Technical Rep, Gabriel Whittle.

BIM Objects

iKoustic also supply a selection of BIM objects via our NBS profile, which can be found here.

Important Information

Our products contain a high level of mass. If there are any structural concerns you will want to consult a Structural Engineer to discuss your requirements.

*Our Typical Performance Results and Noise Reduction Guidance are provided to indicate the results that have been achieved in previous tests but are not guaranteed to a specific site as multiple factors can affect this, you can view their variants on our ‘Featured Systems’ tab.