Best acoustic underlays (top 7 picks & when to use them)

Does acoustic underlay make a difference?

After decades of working in soundproofing and attending to thousands of customers, this is one of the most common questions I get asked from people looking to soundproof their floor. Can acoustic underlay really make a difference?

The short answer is yes. Acoustic underlay can be used to block airborne and impact sounds.

Our top acoustic underlays for 2024

MuteMat 3

Cost per m2 £33.29

The best all-around acoustic underlay for impact and airborne!

MuteMat 2

Cost per m2 £23.57

Excellence impact resistance with airborne performance

MuteBarrier 10

Cost per m2 £13.85

Our budget-friendly option with great airborne noise resistance

How acoustic underlay works

Acoustic underlays can block airborne noises and impact noises. Airborne noises would be talking, music or a TV, while impact noises are usually footsteps. It’s really important, at this early stage, to understand which type of noise you’re dealing with.

While a heavy and dense acoustic matting, like the MuteBarrier 10, is great for airborne sound reductions, it can’t block impact noises. Similarly, our OSF rubber crumb matting is perfect for impact, but not airborne.

Therefore, to know if acoustic underlay can make a difference in your home, you need to first decide which type of noise you are dealing with. I will be reviewing different materials so you can understand which will help you reduce your specific noise issue.

Important underlay features to block airborne noise

- High mass per m2

- Slim design to reduce headspace lost

- Two different layers for high-mass materials

Important underlay features to block impact noise

- Vibration isolation materials

- Does not bottom out to make contact with the existing floor

- No open cell materials

All ‘round best acoustic underlay

MuteMat 3

Cost per m2 £33.29

- 2 Layers of mass

- Closed cell foam

- 12mm thick

- Airborne reduction

- Impact reduction

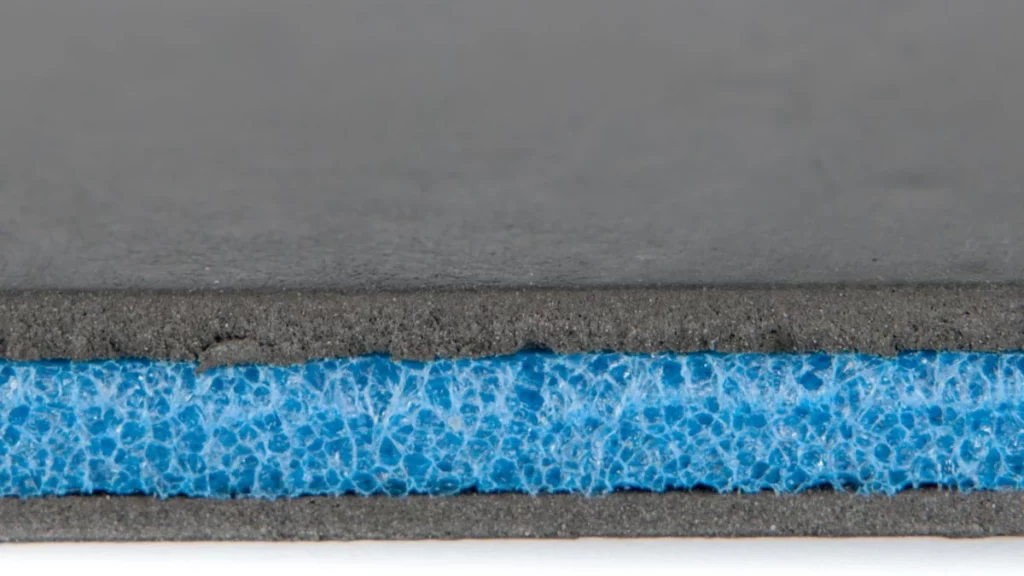

The best acoustic underlay must be the MuteMat 3. This offers a sound reduction for both airborne and impact noise issues. What we love about this underlay, is that it includes two different layers of high mass, as well as, closed-cell foam.

Because this underlay offers a great reduction for both types of noise, it means that the installation is much easier. You get a double benefit while only needing to install one mat! To improve on this further, you can upgrade the flooring with isolation strips on joists and acoustic mineral wool in cavity space.

The acoustic matting is compatible with carpet and hard floor finishes, making it the all-around winner for us. While this mat can do a bit of everything (to a high standard), it’s worth noting that the best option for impact only is a different product, (MuteMat 2), which we come to later.

A potential drawback of this option would be the thickness. While it’s still only 12mm, which is the same as most standard carpet underlays, this is thicker than our other options. For most people, 12mm won’t be too much, but in some cases threshold heights and stair levels can get in the way. That’s when you should consider the MuteMat 2 instead, as it’s 10mm thick.

Best underlay for impact noises

MuteMat 2

Cost per m2 £23.57

- 1 Layer of mass

- Closed cell foam

- 10mm thick

- High for impact

- Good for airborne

If you are most concerned with impact noise, then we would actually suggest the MuteMat 2, instead. This option allows the vibration isolation layer, (closed-cell foam), to be in direct contact with the subfloor. The advantage this offers is a greater impact reduction than the MuteMat 3, which has a hard layer in contact with the floor instead.

Unlike MuteMat 3, this only has two layers of soundproofing. This does make the underlay cheaper, by £10 per sheet, which is a considerable saving. It also means the matting is slimmer, at 10mm thick. However, the one fewer layers of mass loaded vinyl means there is less resistance to airborne noises, like talking.

Best acoustic underlay for airborne noise

Our review wouldn’t be complete without an underlay to just target airborne noise. While you best underlay is still MuteMat 3, if you don’t need to block a huge amount of airborne noise, need to save money and have no impact noise to stop, then this is your solution!

The MuteBarrier 10 is a 10kg/m2 material. This high mass means it’s great for reflecting airborne noises away. However, it can’t reduce impact noise, so make sure you know what you need!

To improve this option even further, you could also include a layer of visco-elastic membrane, like MAD 4. This will increase the price, but also increase the mass and, therefore, your performance!

Best acoustic underlay for carpet 2024

Happily, our two best acoustic underlay picks for this year are both great solutions for a carpet finish. You can lay carpet directly over MuteMat 2 and MuteMat 3 without needing another layer.

Unlike a standard carpet underlay, both of our top picks won’t bottom out under foot. This prevents your foot thudding into the subfloor and creating a loud noise. The reason a standard underlay can’t provide acoustic benefits is that they use an open cell structure. This can’t isolate the vibrations properly as the product will bottom out. It also means the material will become compressed with use and performance even worse.

Like a standard carpet underlay, our two best options of MuteMat 2 and MuteMat 3 still provide a cushioned walking experience. This ensures great comfort under foot, without the elephant noise issues. To block more noise and improve your floor soundproofing, we would also suggest you consider acoustic mineral wool inside cavity spaces. This will strengthen the whole system by reducing reverberation inside cavity spaces.

Top acoustic underlay for laminate flooring

MuteMat OSF 750-10

Cost per m2 £21.67

- Rubber crumb

- Recycled material

- Great for impact

- Does not bottom out

While we could wax lyrical about MuteMat 2, (again!), we are placing a different acoustic underlay here. The MuteMat OSF 750-10 is an alternative when it comes to impact vibrations paired with a laminate floor finish. The OSF range offers something valuable and unique: they are made from recycled tire rubber.

This rubber crumb is not only a fantastic repurpose of waste materials, it also offers a ‘springy’ surface that is perfect for impact vibration isolation. The OSF 10 is 10mm thick, so it’s not unusually thick or difficult to fit. The material is £21 per m2 (at the time of writing in 2024), making it the cheapest solution so far!

We love this option for its simplicity, high performance, and environmental benefits. To lay an LVT floor directly over the top, a slim 6mm boarding is laid first to give your flooring more stability. If you want to fit LVT directly over an underlay, then we have two excellent LVT specific underlays here.

Top acoustic underlay for wooden floors

Gold floor system

Cost per m2

- Total protection

- Prevention of reverberation

- Vibration isolation

- High mass solution

Lastly in this round-up of the best acoustic underlays, we need to look at timber floors. For this, we are going to suggest the MuteMat 3. Now, we aren’t going to stop there, while we already know that the MuteMat 3 is a great option to reduce both types of noise, when it comes to a floorboard finish, we can do one better!

The very best solution we can create for floor soundproofing goes even further than acoustic underlay. We would lift the floorboards and pop them to one side. Then, we can get acoustic mineral wool into the cavity space which will stop the drum effect.

From there, we will add isolation strips to the joists. These are excellent for vibration isolation of impact noises because they ‘float’ the new floor layer. While MuteMat 2 also offers this, doubling up with isolation strips is going to further improve the impact reduction rating. We can then lay a new rigid layer and the MuteMat 3 before laying down the floorboards again.

Now, of course a drawback of this method is first the cost and secondly the system depth. However, when it comes to the best of the best, both variables will always increase. You don’t at all have to go for this all singing all dancing solution, but if you’re out to block as much noise as you can, then this is the best solution for 2024.

How does acoustic underlay block noise?

To get the best acoustic underlay, we test to see how much mass they have and how much load compression they can take. For airborne resistance, we need to ensure the material has a high mass per m2. Ideally, we would use a material with 5kg/m2 and 10kg/m2. By using two different materials, we get a better performance as each level of mass can resist a different frequency of sound.

For impact noise, we test for load compression. This means we can see if the material will bottom out and transfer your thudding feet to the room below. We can also see if the material is able to repeatedly spring back and provide a long service life.

Will a double layer of underlay double my sound reduction?

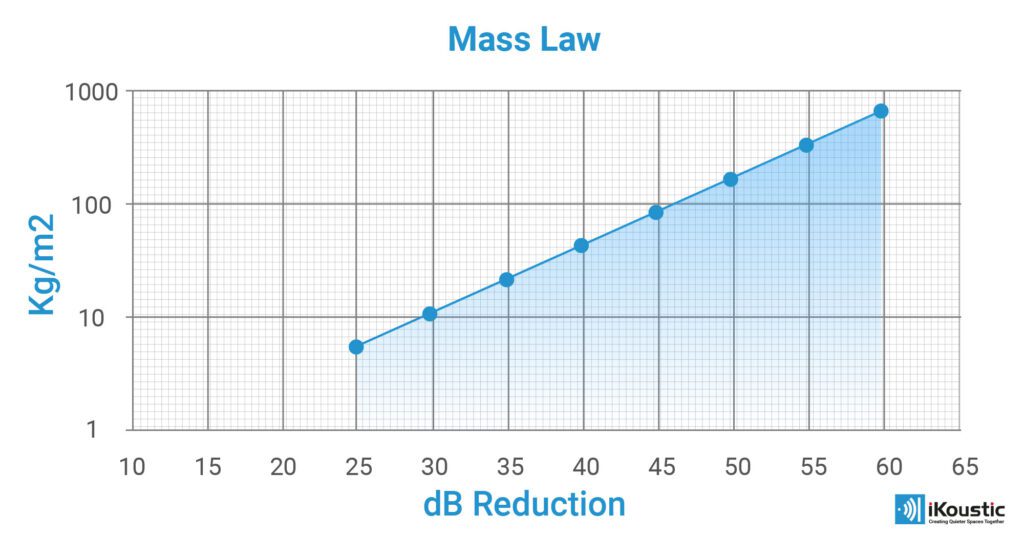

Sadly, no. This is all to do with mass law and is something we keep in mind when designing the best acoustic underlay. Mass law tells us that if you double the mass of a material, you can gain an extra 5dB of sound reduction.

So, our MuteBarrier 5 provides a 25dB reduction and the MuteBarrier 10 a 30dB reduction. This is why it becomes progressively harder to block more noise (and retain space!). To combat this issue, you should consider upgrading your acoustic underlay into a floor soundproofing system.

The huge benefit of using a full system over just an underlay is that we can use two other soundproofing methods besides only mass. By utilizing decoupling and absorption, we are able to control sound and improve the performance of your acoustic underlay.

De-coupled Mass

Once you de-couple mass from an existing surface you start to reduce the transfer of vibrations more efficiently and therefore the mass can then increase the performance above the restraints of Mass law. In real terms, this de-coupling is with a full floating floor system or mimicking the same kind of de-coupling.

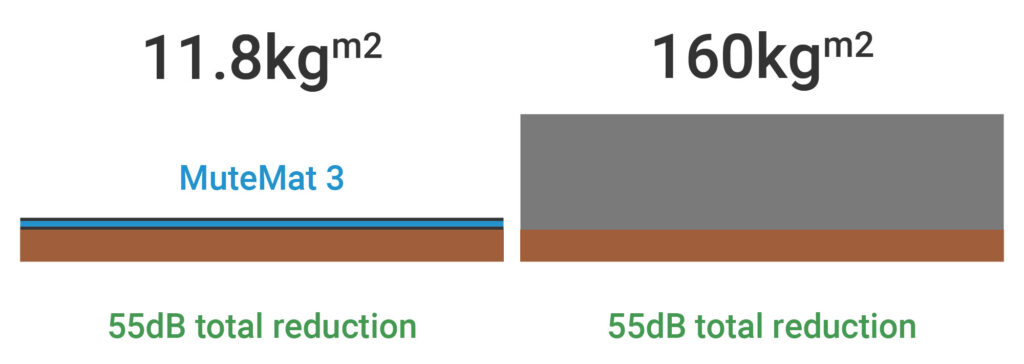

With on-site testing our MuteMat 3 has achieved a 5dB improvement on a floor which is already performing at 50dB taking that total result to 55dB. According to mass law, you would need an additional 160kg/m2 if this was a similar mass attached directly to 1 solid piece of mass but due to the de-coupling of the system, you can achieve a much higher reduction.

Another way you can efficiently improve the sound reduction is by using the Tecsound in conjunction with the MuteMat to add further mass and vibration dampening. This combination of acoustic underlays allows you to achieve far higher results with the thinnest soundproofing products.

How to fit an acoustic underlay

Watch us install the MuteMat systems available.

- Starting in one edge of the room, roll out the Tecsound, you may find it easier to cut the roll into smaller manageable pieces.

- If possible, ensure the Tecsound layer is staggered over any joins in the subfloor.

- Peel back the Tecsound film and adhere to the floor, ensuring a smooth application.

- If any air bubbles are trapped underneath, push to the side or make a small cut and stick back down.

- Continue laying the Tecsound until your subfloor is completely covered, laying each sheet/roll right up to the previous.

- Fold the perimeter flanking band back over the Tecsound. – Cut the flanking band vertically in corners to help fold it back.

- Fit the skirting boards to the perimeter, applying slight pressure down onto the folded flanking band.

- Using a sharp blade cut off the remainder of the perimeter flanking band.

- Peel and stick the self-adhesive gripper strips around the perimeter of the room, leaving a 2-5mm gap between the wall and the gripper strip.

- Seal the gap left around the perimeter with acoustic sealant.

- Loose lay / glue the MuteMats in a brick bond pattern.

- Tape all joints on the MuteMats using cloth tape.

- Attach the gripper rods to the gripper strips and fit the carpet as usual. – An additional underlay can also be used if required.

Tips and tricks to fit an acoustic underlay

I always work to make an airtight seal against the wall, here’s how it’s done: Offer your acoustic underlay up to the wall, place a washer on top of the mat, and use the inside of the washer to draw a line down the mat by dragging the washer along the wall to get a replica of the shape and curve of the wall. This will give you an air-tight seal against the wall.

A little trick I like to use to for fitting the end mats of acoustic underlay: place the last mat under the previous mat to get the exact length needed to finish against the wall.

Can I use an acoustic underlay on the stairs?

Yes, you can use acoustic underlay on stairs to reduce creaking noises from impact. It is best, however, to treat your staircase and first take remedial action to reduce the creaking noises. Acoustic underlay can then be cut and fitted to each tread which will cushion the foot. If you want to know more about stair soundproofing you can read our blog about it here: https://www.ikoustic.co.uk/blog/reduce-stair-noise/