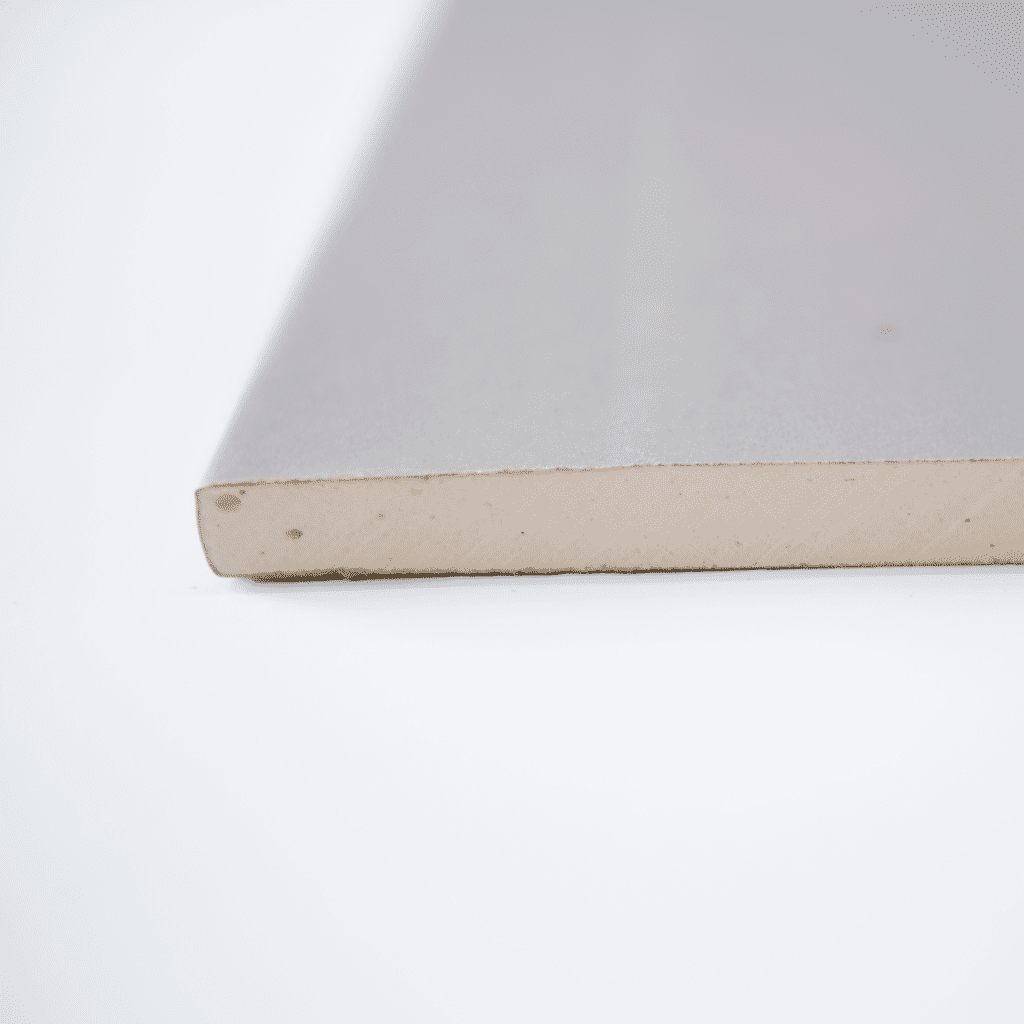

Soundproof Plasterboard 15mm (Half-board)

Shipped by iKoustic from the UK

£14.75

£17.70 inc. VAT

- Acoustic plasterboard for soundproofing.

- Can be used on floors and ceilings.

- Reduces airborne sounds (e.g. music, tv & talking).

- Great for internal stud walls or as part of a system.

- Higher mass than standard plasterboard improves acoustic properties

- Compliant with both Part E Building Regulations (England, Wales, Northern Ireland and the Republic of Ireland).

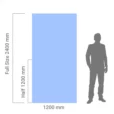

- Dimensions: 1200mm x 1200 mm x 15mm

- Weight: 18kg per Board.

- Noise reduction: Up to 38dB on a single course brick wall* What’s this?

Soundproof Plasterboard 15mm (half-Board)

Soundproof or acoustic plasterboard is used in a variety of soundproofing systems or can be used on its own. It differs from traditional plasterboard by having a higher mass. This high mass make-up assists in the reduction of airborne noise like talking or TV noise.

Acoustic Plasterboard Coverage Calculator

Tape & joint or skim

Our acoustic plasterboards have a tapered edge. This means you’re able to tape and joint as a speedier way to finish your project. Our boards are also ready for traditional skimming.

Cost-effective Mass

Adding mass is a key aspect of soundproofing but high mass products can get costly. Soundproof plasterboard is one of the cheapest forms of mass you can add to a soundproofing system.

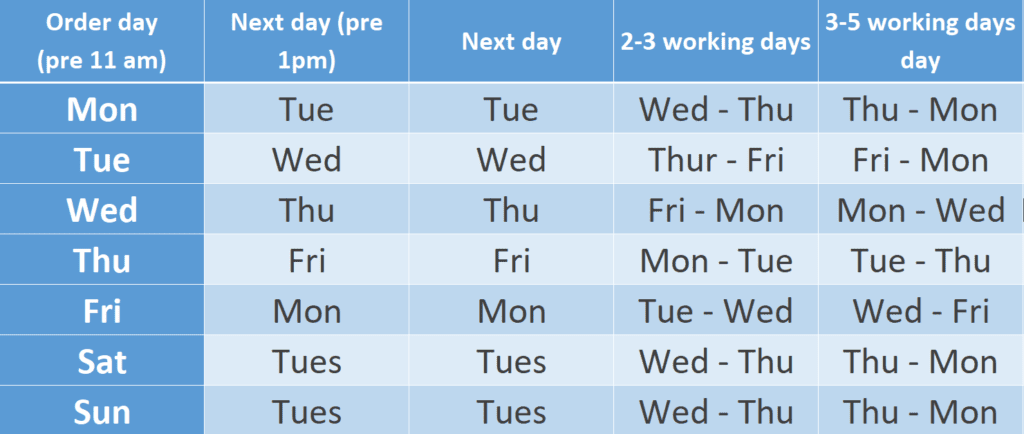

Same day dispatch

Half-sized soundproof plasterboards are shipped on a pallet. Unlike others, we hold stock of all of our products ready to dispatch same day Monday to Friday. We also offer next-day delivery for orders placed before 1pm Monday to Friday.

If you are looking to specify this product for a build, please refer to our downloads tab for technical product or systems information.

Technical Support

Should you require further technical assistance in specifying our products, please contact us and ask for our Technical Rep, Gabriel Whittle.

BIM Objects

iKoustic also supply a selection of BIM objects via our NBS profile, which can be found here.

Important Information

Our products contain a high level of mass. If there are any structural concerns you will want to consult a Structural Engineer to discuss your requirements.

*Our Typical Performance Results and Noise Reduction Guidance are provided to indicate the results that have been achieved in previous tests but are not guaranteed to a specific site as multiple factors can affect this, you can view their variants on our ‘Featured Systems’ tab.