Rockwool Acoustic Mineral Wool RW3 25mm 60kg/m³

Shipped by iKoustic from the UK

£47.97

£57.56 inc. VAT

-

- Soundproof Mineral wool to be used in soundproof partitions.

- A crucial component for all soundproofing systems with joists, battens, acoustic cradles or stud-frames.

- Euroclass A1 fire rating.

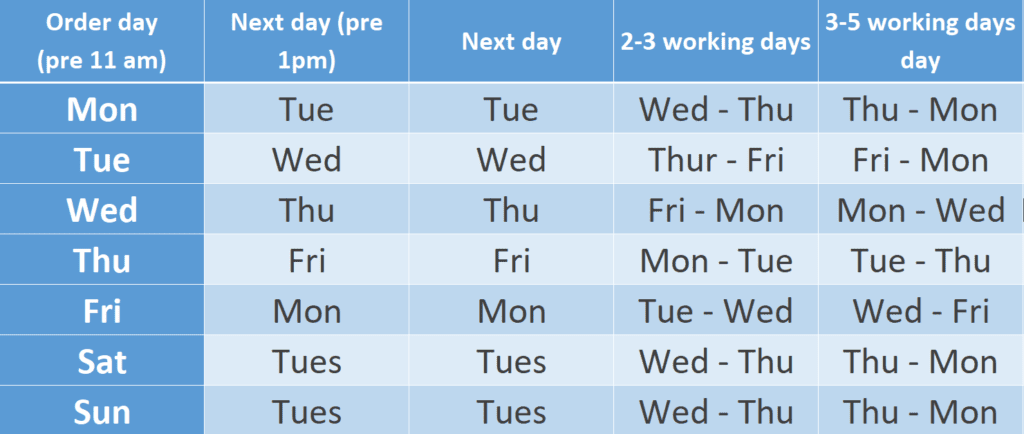

- Dimensions: 1200mm x 600mm x 25mm. (16 per bale – 11.52m2)

- Weight: 20kg

Rockwool Acoustic Mineral Wool RW3 25mm 60kg/m³

Rockwool Acoustic Mineral Wool (RW3) (60kg per m3) is high-density acoustic mineral wool that is used to treat cavities, between flooring joists, stud-frame walls and battened ceilings.

Acoustic Mineral Wool works by lessening sound energy helping to decrease the remaining noise ‘bouncing’ around inside the cavity and amplifying (like a drum). We recommend using Rockwool RW3 as part of a system or to reduce Flanking transmission.

Acoustic Mineral Wool Coverage Calculator

Bass frequency absorption

Bass frequencies are difficult to treat with soundproofing. Rockwool RW3 has a good absorption coefficient at bass frequencies, making it an essential upgrade to most soundproofing systems.

Multi-use application

Whether you are treating your wall, floor or ceiling Rockwool RW3 is ideal to fill joists, stud frames, battens and acoustic cradles.

Easy to install

Cut your slabs slightly larger than the application area and simply pressure fit them to hold them in place.

A1 fire rated

Rockwool RW3 has a Euroclass A1 fire rating, meaning it is completely non-combustible. This is an excellent safety feature and is often required for building regulations.

Thermal insulation

Alongside its enhanced acoustic capability acoustic mineral wool carries the same thermal insulation properties as its standard counterpart. Rockwool RW3 has a thermal conductivity of 34 W/mK.

Other thicknesses we offer:

| Mineral wool thickness | 100mm | 75mm | 50mm | 25mm |

| Slabs per bale/m2 | 4 Slabs (2.88m2) | 6 Slabs (4.32m2) | 8 Slabs (5.76m2) | 16 Slabs (11.52m2) |

Find out more information about Rockwool Acoustic Mineral Wool by downloading the guide below.

If you are looking to specify this product for a build, please refer to our downloads tab for technical product or systems information.

Technical Support

Should you require further technical assistance in specifying our products, please contact us.

BIM Objects

iKoustic also supply a selection of BIM objects via our NBS profile, which can be found here.

Important Information

Our products contain a high level of mass. If there are any structural concerns you will want to consult a Structural Engineer to discuss your requirements.

*Our Typical Performance Results and Noise Reduction Guidance are provided to indicate the results that have been achieved in previous tests but are not guaranteed to a specific site as multiple factors can affect this, you can view their variants on our ‘Featured Systems’ tab.