MuteMat® 2 Soundproofing Underlay

Shipped by iKoustic from the UK

£33.95

£40.74 inc. VAT

- Floor soundproofing underlay.

- Reduces impact sounds (e.g. heavy footsteps, washing machines).

- Ideal for soundproofing flats and apartments.

- Use with carpet, wood floor, laminate and more.

- Compliant with both Part E Building Regulations (England, Wales, Northern Ireland and the Republic of Ireland).

- Dimensions: 1200mm x 1200mm x 10mm (1.44m2).

- Weight: 12kg per mat.

- Noise reduction: 47dB impact and 45dB airborne as part of a system. Whats this?

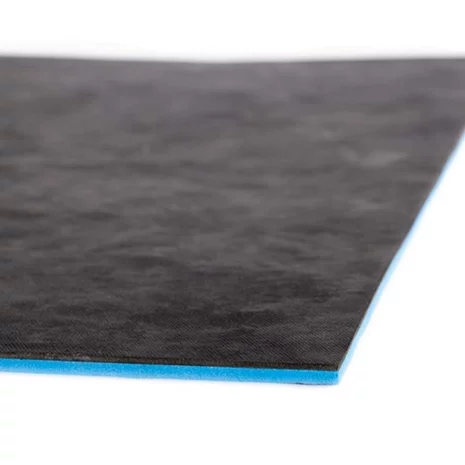

MuteMat® 2 Soundproofing Underlay

MuteMat 2 is a 10mm acoustic underlay that can be laid on top of timber or concrete floors to reduce Impact and airborne noise. Carpet, wood, tile and vinyl flooring can be laid on top of the MuteMat 2. You can watch our installation video to see how it’s done below.

MuteMat Calculator

For use with most flooring

MuteMat 2 soundproof underlay can be used with most flooring types. Carpet, wood flooring, engineered wood flooring over 18mm, porcelain tiles* LVT* and laminate*. *requires overboarding with plywood.

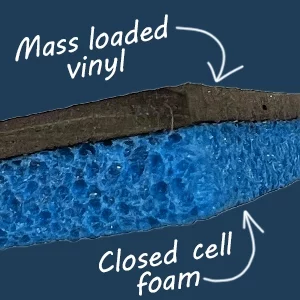

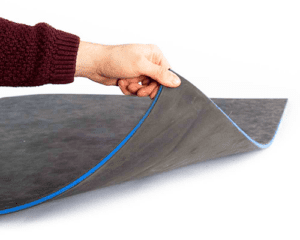

2 layers of soundproofing

MuteMat 2 features closed cell foam topped with a layer of high-density mass-loaded vinyl. The grey mass-loaded vinyl works to dampen and break down airborne sound. The blue foam compresses to absorb impact energy.

Slim Design

MuteMat 2 10mm acoustic underlay is designed to keep floor height to a minimum. Delivering acoustic performance in a low-profile package!

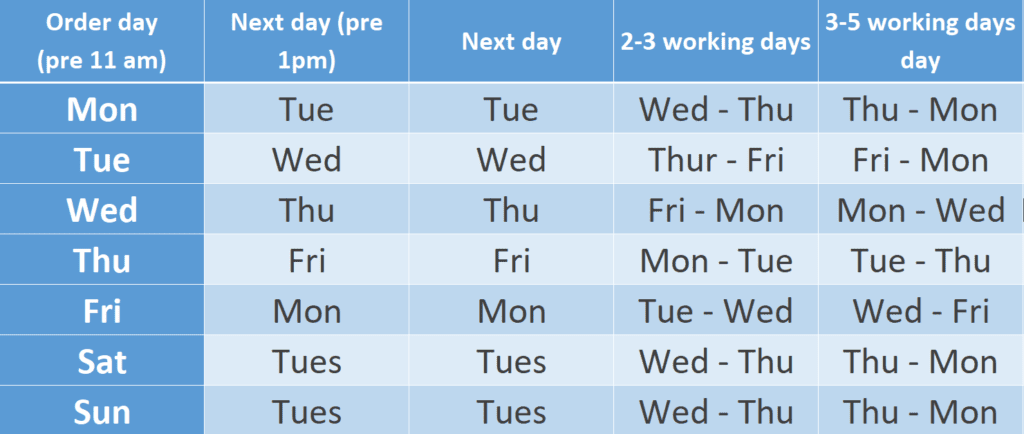

Same day dispatch

MuteMat 2 is shipped on a pallet. Unlike others we hold stock of all of our products ready to dispatch same day Monday to Friday. We also offer next day delivery for orders placed before 1pm Monday to Friday.

Closed cell foam

MuteMat 2 utilises closed cell foam. Closed cell foam is denser and more durable than open cell foam. Making it more effective as a soundproofing material and helping it stand up to everyday use.

Soundproofing Underlay Comparision

| Image | Product | Thickness | Airborne rating | Impact rating | Timber performance | Concrete performance | Roll/sheet size | m2 weight | Units per pallet | Delivery lead time |

|---|---|---|---|---|---|---|---|---|---|---|

|

MuteMat 2 | 10mm |

3/5 |

4/5 |

48dB | 49dB | 1.44m2 | 7.5kg | 75 | 2-3 days |

|

MuteMat 3 | 12mm |

3.5/5 |

4/5 |

52dB | 54dB | 1.44m2 | 12.5kg | 50 | 2-3 days |

Find out more information about MuteMat 2 by downloading the guides below.

If you are looking to specify this product for a build, please refer to our downloads tab for technical product or systems information.

Technical Support

Should you require further technical assistance in specifying our products, please contact us and ask for our Technical Rep, Gabriel Whittle.

BIM Objects

iKoustic also supply a selection of BIM objects via our NBS profile, which can be found here.

Important Information

Our products contain a high level of mass. If there are any structural concerns you will want to consult a Structural Engineer to discuss your requirements.

*Our Typical Performance Results and Noise Reduction Guidance are provided to indicate the results that have been achieved in previous tests but are not guaranteed to a specific site as multiple factors can affect this, you can view their variants on our 'Featured Systems' tab.