Tecsound S Band

Shipped by iKoustic from the UK

£9.97

£11.96 inc. VAT

- Dimensions: 6m x 50mm x 2.5mm

- Weight: 400g

- For: Homes, workplaces, industrial developments, and specialist audio environments.

- Compliance: Compliant with both Part E Building Regulations (England, Wales, Northern Ireland and the Republic of Ireland).*

- Installation: Please see our installation tab below.

- Where: Multi-use application on walls, floors and ceilings, with special focus on decoupling the structure to improve acoustic performance.

Tecsound S Band

The Tecsound S Band is an essential component for the damping of vibration in metal structures and decoupling buildings from stud-frames and flooring by attaching to joists.

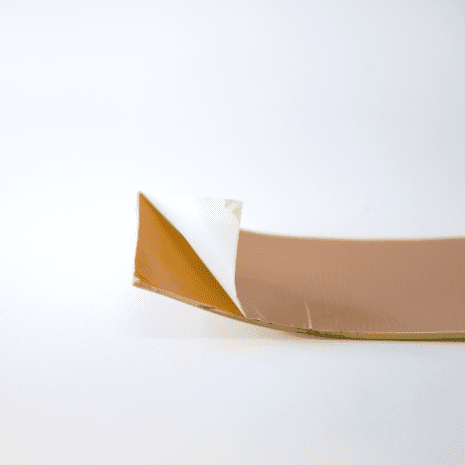

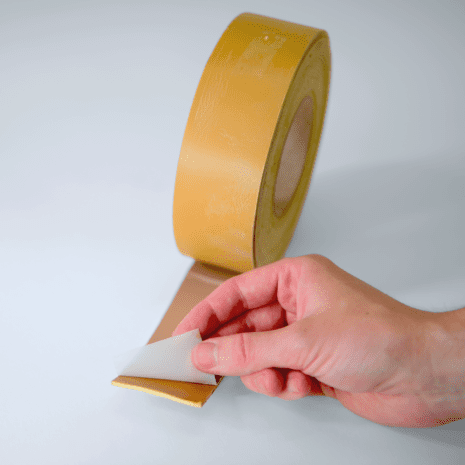

Tecsound S Band is a visco-elastic material. This means it is a viscous material, part way between a solid and a liquid, and has elastic properties. This means that it returns to its original form when stresses within its limits are applied, like pulling an elastic band, but if you pull it too hard it will break. It comes with self-adhesive and will apply to an extensive range of building materials. This creates a great alternative for those who only need to apply small strips to certain areas to control vibration, instead of using Tecsound which comes in big sizes. Tecsound S Band will not falter under expected weights in most applications that are common in households and commercial properties. If significant weights are applied that are not usually expected, then do let us know.

Self Adhesive Tecsound S Band

The self-adhesive coating makes installing Tecsound S Band much easier. Simply peel the backing off and roll out.

Vibration dampening

One of the most remarkable features of this product is its ability to dampen vibration on metal structures. Vibration and resonance are noticeably dissipated with Tecsound.

Mold, moisture and fungus resistant

Though we do not recommend installing in wetrooms or places expecting regular damp. Tecsound does offer some mold moisture and fungus-resistant properties.

Reduces airborne and impact noise

Most soundproofing materials can only reduce impact or airborne noise but due to its unique properties, Tecsound is effective against both.

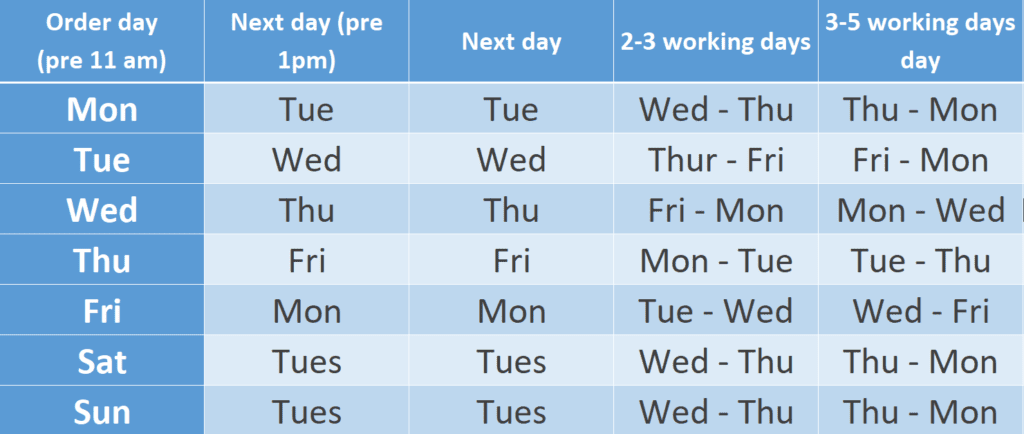

Tecsound UK shipping

Tecsound S Band is shipped on a pallet. Unlike others, we hold stock of all of our products ready to dispatch same day Monday to Friday. We also offer next day delivery for orders placed before 1pm Monday to Friday.

Find out more information about Tecsound S Band by downloading the guides below.

If you are looking to specify this product for a build, please refer to our downloads tab for technical product or systems information.

Technical Support

Should you require further technical assistance in specifying our products, please contact us.

BIM Objects

iKoustic also supply a selection of BIM objects via our NBS profile, which can be found here.

Important Information

Our products contain a high level of mass. If there are any structural concerns you will want to consult a Structural Engineer to discuss your requirements.

*Our Typical Performance Results and Noise Reduction Guidance are provided to indicate the results that have been achieved in previous tests but are not guaranteed to a specific site as multiple factors can affect this, you can view their variants on our ‘Featured Systems’ tab.