MuteMat® USP 750-08

Shipped by iKoustic from the UK

£183.95

£220.74 inc. VAT

-

- Performance: Up to 26dB reduction for impact*.

- Dimensions: 10m x 1.3m x 8mm (13m2)

- Weight: 59kg.

- For: Great and small scale residential and commercial projects looking for soundproof under screeds.

- Compliance: Compliant with both Part E Building Regulations (England, Wales, Northern Ireland and the Republic of Ireland).*

- Installation: Please see our installation tab below.

- Where: For under screed projects requiring isolation from low-frequency vibration and impact noise.

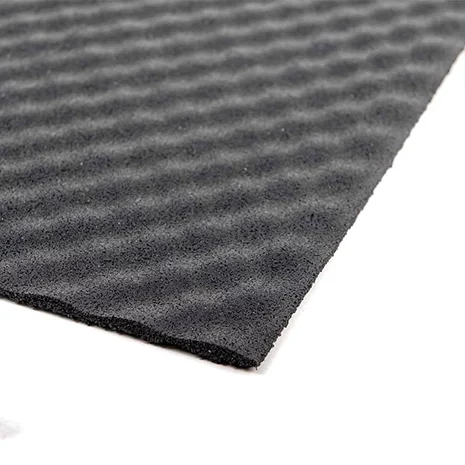

Our pimpled under screed underlay specialised for controlling excessive noise issues in concrete structures.

Up to 19dB reduction for impact*.

MuteMat® USP 750-08

MuteMat® USP 750-08 is our robust, pimpled acoustic under screed resilient layer designed for achieving a greatly improved impact noise reduction between the floating concrete screed and structural concrete slab layers. Its high performance comes from it’s deviated pimpled structure which is found at both 8mm and 4mm – helping to secure minimum points of contact between the two layers. As a dense and robust product it maintains a low level of compressibility and when subjected to high points loads it maintains its acoustic performance making it suitable for a wide range of applications in residential, commercial and industrial structures, especially where particular low-frequency vibration that large machinery generates as the floated floor design helps to isolate these acoustic issues.

Consistent Thickness

MuteMat® OSF 03 consistent thickness makes for easy application.

Acoustic underscreed UK shipping

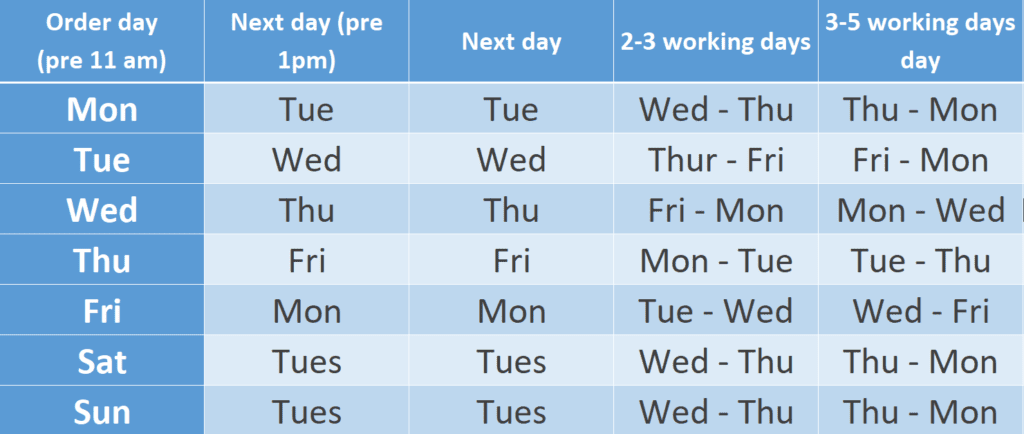

MuteMat® USP is shipped on a pallet. Unlike others, we hold stock of all of our products ready to dispatch same day Monday to Friday. We also offer next day delivery for orders placed before 1pm Monday to Friday.

High recycled content

Each roll of MuteMat® USP contains 15.73 recycled tires. You can feel good about your purchase knowing that you’re keeping tires out of landfills and giving them a second life.

Find out more information about MuteMat USP by downloading the guides below.

If you are looking to specify this product for a build, please refer to our downloads tab for technical product or systems information.

Technical Support

Should you require further technical assistance in specifying our products, please contact us and ask for our Technical Rep, Gabriel Whittle.

BIM Objects

iKoustic also supply a selection of BIM objects via our NBS profile, which can be found here.

Important Information

Our products contain a high level of mass. If there are any structural concerns you will want to consult a Structural Engineer to discuss your requirements.

*Our Typical Performance Results and Noise Reduction Guidance are provided to indicate the results that have been achieved in previous tests but are not guaranteed to a specific site as multiple factors can affect this, you can view their variants on our ‘Featured Systems’ tab.