MuteClip® LP Ceiling Isolation Clips

Shipped by iKoustic from the UK

£6.95

£8.34 inc. VAT

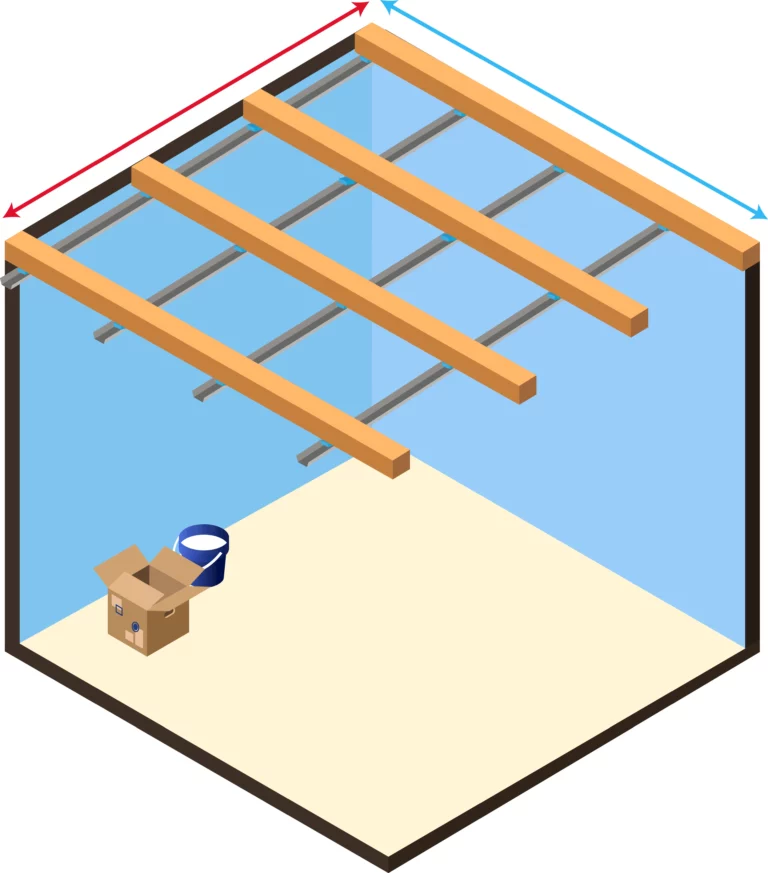

- Soundproofing clips for building clip and channel independent frames

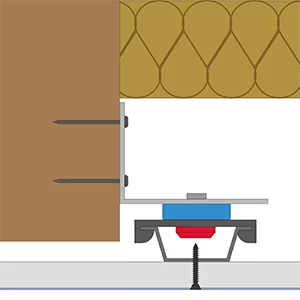

- For creating a low profile acoustic dropped ceiling (as little as 5mm drop)

- MuteClip® LP system reduces airborne sounds (e.g. music, tv & talking).

- MuteClip® LP system reduces impact sounds (e.g. heavy footsteps, washing machines).

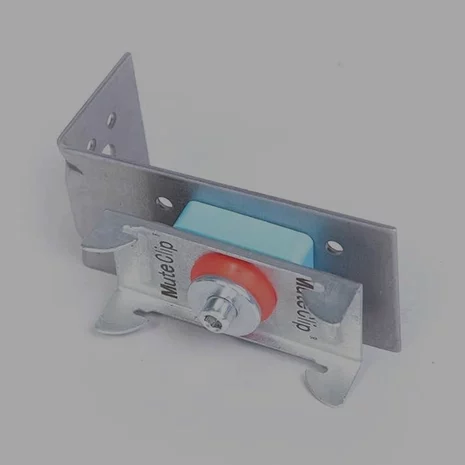

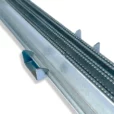

- Works exclusively with MuteClip® Channel

- Compliant with both Part E Building Regulations (England, Wales, Northern Ireland and the Republic of Ireland).

- Dimensions: 105mm x 50mm x 74mm

- Weight: 174 grams

- Noise reduction: 35 dB impact 60dB airborne*. What’s this?

MuteClip® LP | Ceiling Isolation Clips

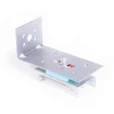

Our MuteClip® LP isolation clip systems deliver the highest standard of soundproofing we offer. Isolation clips and channels are used to build a ‘de-coupled’ frame for wall and ceiling soundproofing. Plasterboard or other soundproofing materials can be installed onto this ‘de-coupled’ frame.

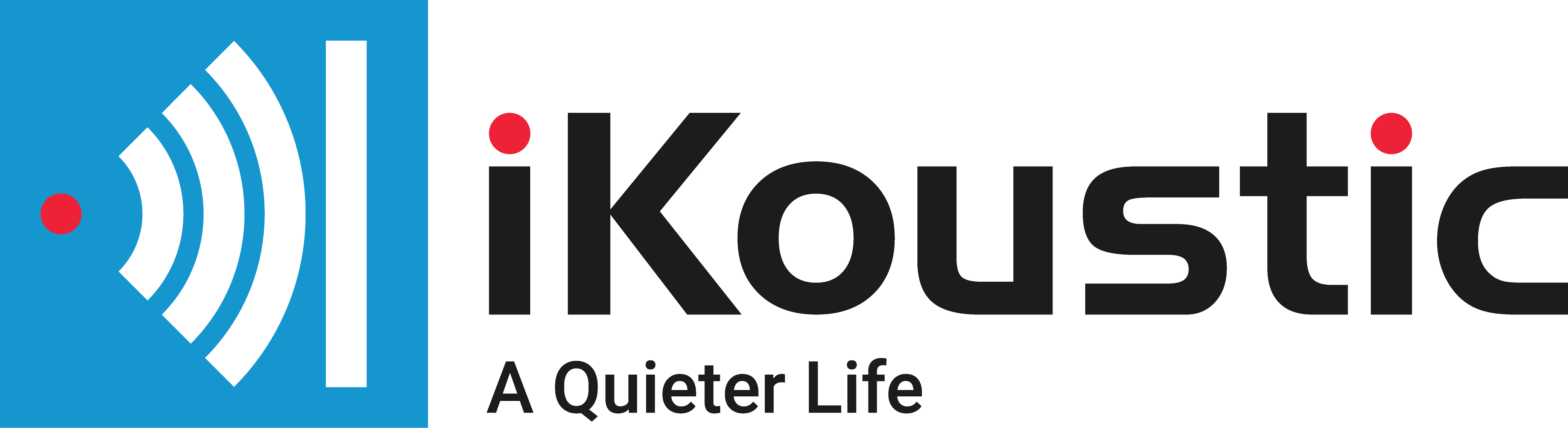

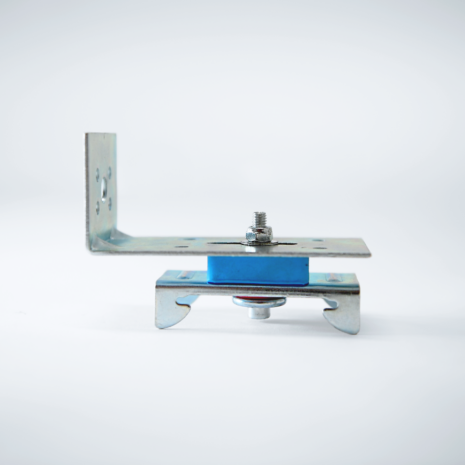

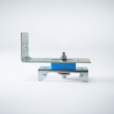

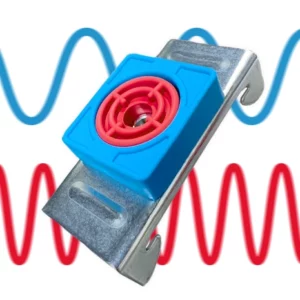

The MuteClip® is backed with dual-density silicone. This acts as a shock absorber surrounding the fixing and buffering the metal clip. The MuteClip® Channel is then ‘clicked’ into the MuteClip® providing a slimline and ‘de-coupled’ frame for plasterboards to be attached to.

All of this works to reduce the sound vibrations able to transfer through your wall or ceiling and into your space.

MuteClip® LP Isolation Clip Calculator

Use our handy calculator to see how many MuteClip® and Channels your project will require.

Dual Density Silicone

Silicone acts as a buffer between the screw fixing and the Clip and Channel. We incorporate two different density’s into our design that perform better at different frequencies. Giving you the best of both worlds!

Reduces loss of ceiling height

Get the benefits of MuteClip® in a low-profile package so you can reduce the amount of ceiling height you lose.

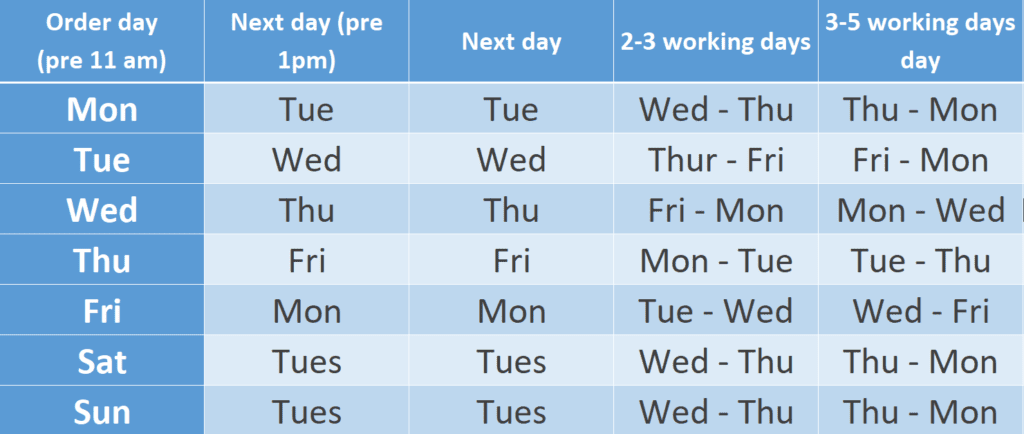

Soundproof Panels UK Delivery

We hold stock of all of our products ready to dispatch same day Monday to Friday. We also offer next-day delivery for orders placed before 1 pm Monday to Friday. Please note MuteClip® Channels must be shipped on a pallet.

Effective against high and low frequencies

MuteClip® LP systems perform well against high frequencies and the more challenging low bass frequencies.

Use as part of a soundproofing system

The MuteClip® range is designed to be used as a part of multiple systems For soundproofing walls and ceilings. Click here to see which system is right for you.

Videos and Downloads

Product Data

Download our product data guide and learn more about the MuteClip®.

Installation Guide

Download our installation guide to learn how to install MuteClip® products.

Performance guide

Download our product data guide and learn more about the MuteClip®.

MuteClip Chanel Data

Download our product data guide and learn more about the MuteClip®.

Find out more information about MuteClip LP by downloading the guides below.

If you are looking to specify this product for a build, please refer to our downloads tab for technical product or systems information.

Technical Support

Should you require further technical assistance in specifying our products, please contact us.

BIM Objects

iKoustic also supply a selection of BIM objects via our NBS profile, which can be found here.

Important Information

Our products contain a high level of mass. If there are any structural concerns you will want to consult a Structural Engineer to discuss your requirements.

*Our Typical Performance Results and Noise Reduction Guidance are provided to indicate the results that have been achieved in previous tests but are not guaranteed to a specific site as multiple factors can affect this, you can view their variants on our ‘Featured Systems’ tab.